The FSO Online measurement system is the best solution for Improving dryer performance and fuel consumption in the agri-food industry.

The drying process is of significant importance for the quality of the end product and further material processing. Dryer systems can be placed in different parts of the process depending on specific needs: during drying for storage or before material processing to meet recipe specifications, or during material processing. To control dryer performance, various parameters will indicate if it is necessary to make adjustments.

Areas of Application:

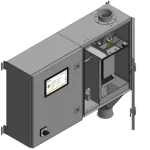

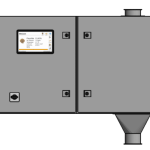

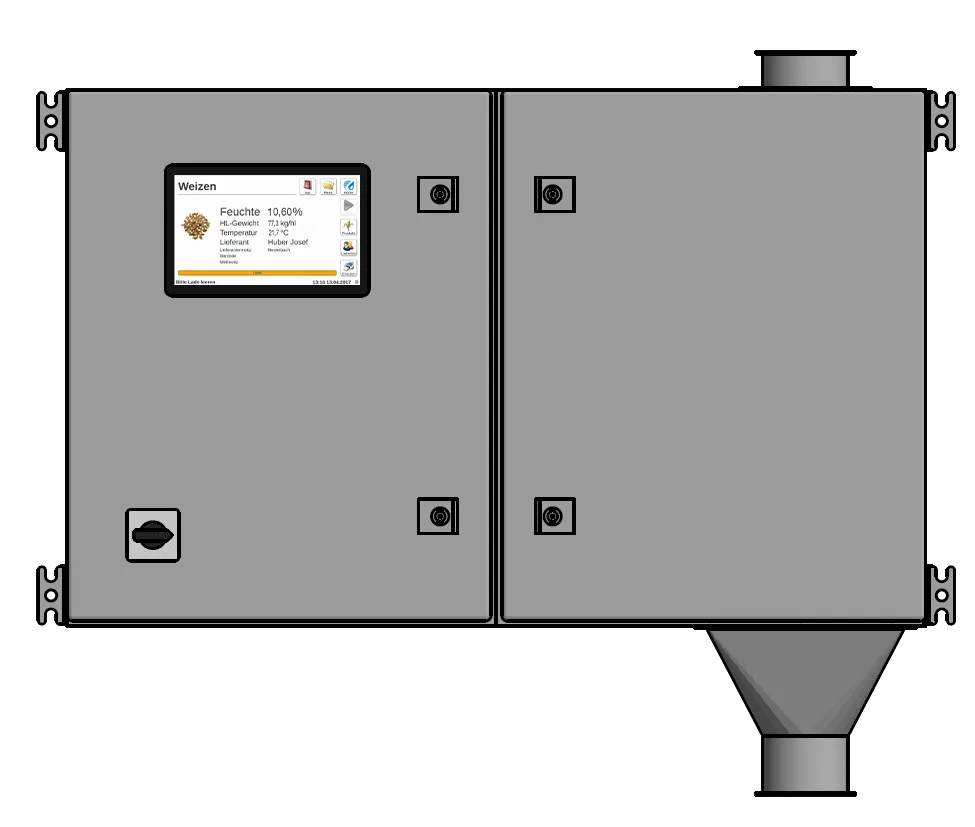

The FSO has been specially developed for online moisture measurement of bulk materials such as grain, beans, rice, seeds and similar. The sensor measures moisture, water content, hectolitre weight and temperature with each measurement.

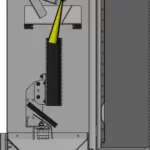

The measuring method is characterized by very high accuracy, reliability and easy operation. The installation is carried out individually according to the existing conditions (see schematic representation of the installation examples as a download). All calibration characteristics (types) common in Europe are stored as standard. Customized characteristic curves can be easily created or adjusted. When changing the material, the corresponding calibration curve can be easily adjusted on the sensor display or from the PC in the control station. Thanks to the online moisture measurement data, the entire system can be operated more efficiently and the quality can be significantly increased.